Semua produk

-

GuillermoSangat baik! Pengiriman cepat! Saya ingin bekerja dengan Anda lagi!

GuillermoSangat baik! Pengiriman cepat! Saya ingin bekerja dengan Anda lagi! -

Perus ColetteIni adalah kesenangan saya untuk melakukan bisnis dengan LiFong, mereka selalu lakukan yang terbaik untuk kita.

Perus ColetteIni adalah kesenangan saya untuk melakukan bisnis dengan LiFong, mereka selalu lakukan yang terbaik untuk kita. -

Robin SeifertSaya suka produk dan layanan yang disediakan oleh LiFong. Mereka benar-benar mengambil minat kami mempertimbangkan.

Robin SeifertSaya suka produk dan layanan yang disediakan oleh LiFong. Mereka benar-benar mengambil minat kami mempertimbangkan. -

SjakIni benar kita menikmati melakukan bisnis dengan Anda.

SjakIni benar kita menikmati melakukan bisnis dengan Anda. -

Kelly MarshLiFong adalah salah satu vendor yang kita inginkan di Cina

Kelly MarshLiFong adalah salah satu vendor yang kita inginkan di Cina -

Raimund SchenkKualitas Produk, Harga Kompetitif, selalu menjadi salah satu pemasok utama kami

Raimund SchenkKualitas Produk, Harga Kompetitif, selalu menjadi salah satu pemasok utama kami

Custom aluminium die castings with cnc milling turning and detailed machining providing precision metal parts fabrication

Hubungi saya untuk sampel gratis dan kupon.

ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

Skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan bantuan online 24 jam.

xDetail produk

| Dimensi | Φ60x110mm | Tegangan Masukan | AC85 ~ 265V 50/60Hz |

|---|---|---|---|

| Peringkat IP | IP55 | Presisi tinggi | +/- 0.005mm Toleransi |

| Toleransi | +/- 0,05mm | ODM | Ya |

| kemampuan mesin | Bagus | Jenis Produk | Pengecoran Aluminium Die |

| Waktu Sampel | 5~7 hari | Jenis | Aluminium Pengecoran Pasir |

| Kekuatan Tarik | 150-300 MPa | Panjang | sebagai desain Anda |

| Efisiensi Bercahaya | 100lm/w | Ukuran Pengecoran Maksimum | Bervariasi, biasanya hingga 10 kg per bagian |

| Suhu Warna | 1000-2000K | ||

| Menyoroti | custom aluminum die castings with CNC machining,precision aluminum die cast metal parts,CNC milled aluminum die cast components |

||

Deskripsi Produk

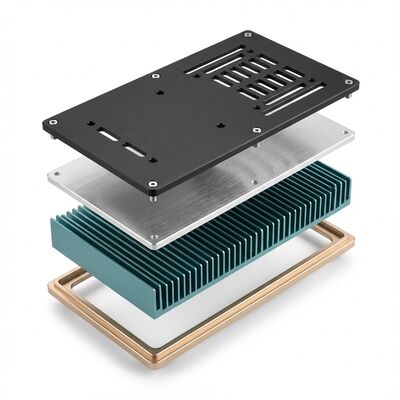

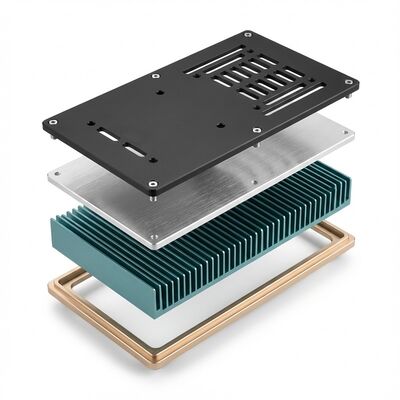

High Precision Aluminium Die Castings

Custom metal aluminum CNC milling and turning machining services for precision metal component applications with detailed machining and superior performance.

Key Specifications & Special Features

Our machined products deliver superior precision, excellent performance, and unparalleled reliability through meticulous craftsmanship and attention to detail.

- Professional Expertise: Over 20 years of experience in custom CNC machining and aluminium extrusion heat sink manufacturing

- Production Capability: Custom manufacturing based on customer drawings with special design services available

- Materials: Aluminum, Stainless steel, Tool steel, Brass, and other specialized materials

- Dimensions: Fully customizable to meet specific requirements

- Processes: Sheet Metal Fabrication including Laser Cutting, Bending, Welding, Etching, and Metal Punching

- Certification: ISO 9001:2015 certified quality management system

- Testing Equipment: Comprehensive quality control with CMM, 2D Projector, Altimeter, Spectrograph, and more

- Customer Service: Professional export sales team with extensive experience serving US, Europe, Japan, and global markets

- Surface Treatments: Deburring, Powder Coating, Anodizing, Heat treatment, Wet Paint, Zinc Plating, E-coating, QPQ, Passivation, Brushing, Electropolishing, Black Oxidation

- Price Terms: EXW, FOB Shenzhen/Guangzhou, CIF

- Delivery: 4-6 days production lead time

- Applications: Metal Recycling Machines, Cutting Machines, Straightening Machinery, Spinning Machinery, Processing Machinery Parts, Forging Machinery, Engraving Machinery, Drawing Machinery, Coating Machinery, Casting Machinery

Company Overview

Specializing in CNC machining parts, cold heading parts, stamping parts, fasteners, and die casting parts with comprehensive manufacturing capabilities.

R&D Strength

15-person R&D team including engineers, project managers, process engineers, and test engineers with proven track record developing projects for Honeywell, BSH, and Whirlpool. Independent testing laboratory for new product development.

| Material Options | Aluminum, brass, copper, zinc, bronze, stainless steel, steel |

|---|---|

| Manufacturing Processes | High speed precision stamping, progressive die, stamping, CNC machining, deep drawing, die casting |

| Finishing Options | Polishing, plating, sand blasting, powder coating, anodizing, hot dip galvanizing |

| Size Capabilities | Fully customized dimensions |

| Sample Time | 15-30 days |

| Production Lead Time | 10 days after sample approval and deposit receipt |

| Packaging | PVC bag + carton |

| Payment Terms | 30% deposit, balance paid before shipment |

Industry Applications

Our products serve diverse industries including Lighting, 3G outdoor antennas, Electronic hardware, Home appliances, Central air conditioning, Transport machinery, and Material handling equipment.

Why Choose Us

Best service and quality with competitive pricing

Leading engineering expertise with stable workforce

100% quality control inspection before shipment

Leading engineering expertise with stable workforce

100% quality control inspection before shipment

Frequently Asked Questions

Q: Are you a factory or trading company?

A: We operate our own factory in Dongguan, China and welcome customer visits.

Q: What are your main products?

A: We specialize in metal stamping parts, laser cutting, sheet fabrication, CNC machining, bending, welding, tool & die making, and assembly products.

Q: Can you support OEM/ODM according to my design drawings?

A: Yes, our professional technical team supports OEM/ODM orders and can manufacture customized products from customer drawings.

Q: How can I get the quotation?

A: We provide quotations within 24 hours during working days. Please include: 3D STEP files and 2D drawings, material requirements, surface treatment specifications, quantity details, and any special packaging, labeling, or delivery requirements.

Q: Can I get samples?

A: Yes, sample orders are available for quality verification and market testing with freight collection payment.

Q: How do you control product quality?

A: Our comprehensive quality control includes: material inspection by IQC, in-process quality checks by IPQC, final quality control by FQC before warehousing, and 100% inspection by OQC before shipping.

Q: What if we receive defective products?

A: If you receive defective products, please provide photos and we will immediately address the issue with our engineering and quality control teams.

Rekomendasi Produk